Candy Packaging

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 7-9 Business Days, Rush |

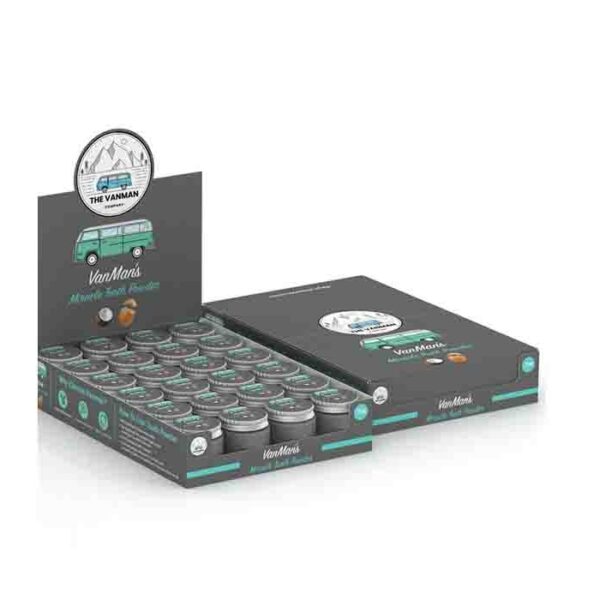

Appearance and Design

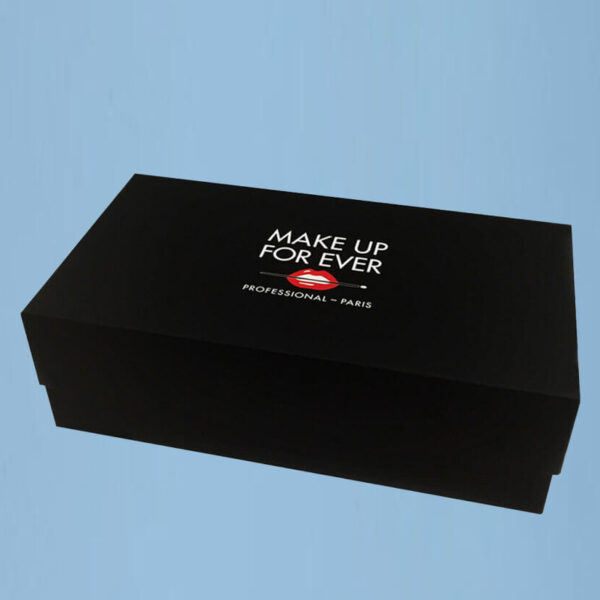

Candy packaging comes in a variety of shapes, sizes, and designs to showcase different confectionary treats. Packaging can utilize bright, vibrant colors and fun graphics to capture a young audience. Things like illustrated characters, animals, or seasonal themes are common. The packaging aims to highlight tempting flavors and ingredients to pique interest. Whether through transparent areas showcasing the candy itself or appetizing images on the wrappers, the packaging advertises the sugary contents within.

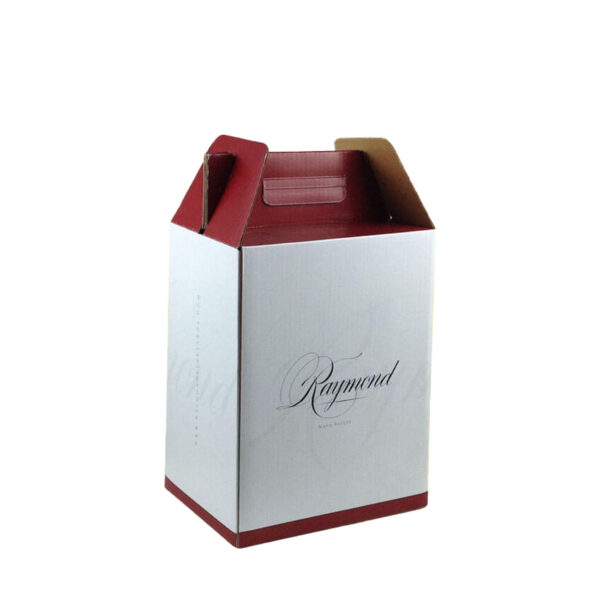

Various finishes can further accentuate the product, like gloss, matte, or metallic. Structural designs also come into play for functionality and visual flair. Things like pouches with a clear display window on front, plastic tubs with removable lids, or resealable bags in a variety of opaque, translucent, and transparent material colors and finishes. The packaging combines aesthetics and practicality.

Size Format & Fill

Candy packaging comes in individual piece counts ranging from single-serves to bulk bags. Things like miniature chocolate bars, lollipops, mints, or gummies often have wrappers designed for one. Treats like chocolates, jelly beans, rock candy, or candy corn may package dozens together in small bags or boxes. Even larger buckets, tins, or bags can contain pounds of candy for big groups or parties.

The size and format aim to match the intended volume and usage. For example, the smaller individually wrapped candies cater more for personal snacking or combined into gift packs. The larger amounts appeal to those stocking up for events or giving as bigger gifts. So whether they are for individual treat yourself moments or mass celebrations with family or friends, the candy package sizes cover different needs.

Materials & Construction

Candy packaging utilizes a variety of paper, plastic, foil, and laminated constructions. Paper options include card stock weight papers in bright white or colors with glossy or matte coatings. Plastics can be flexible films in single layers or combined in laminations with foils or paper. A popular example is combining an inner foil layer with an outer paper layer into one laminated material. The films improve barrier while paper offers aesthetics and printability.

The constructions suit the type of candy and desired shelf life. Things like chocolates with filling need more moisture barrier while hard candies last longer unwrapped. The packaging keeps the contents protected and fresh until opened. The materials also allow branding elements like logos and graphics to feature prominently. So the candy wraps become an extension of the product experience from shelves to snacks.

Conclusion

Candy packaging combines visual, structural, and functional considerations. The designs set a tempting impression while the format and construction maintain quality. Vibrant wrappers present candies as joyful treats while the fill and size meet gifting or personal indulgence needs. So both aesthetic and practical factors come together to make the packaging appeal to candy lovers. The wrappings ultimately promote and preserve the sweet treats within.